To develop Korea's lacquer culture, CEO Lee Ki-sang of ‘OTTSAN’(옻산), developed the world-class refined lacquer for the first time in Korea through 15 years of joint technology development of natural lacquer refining technology that only Japan had. It is a lacquerware company that produces various lacquer household items (such as spoons, kitchenware, and accessories) that have the effect of lacquer, such as anti-cancer and antibacterial properties, under the brand of ‘ottirang’(옻이랑)

■ Purpose of lacquer research and R&D

Although Korean lacquer culture has a history of more than 2,000 years, it is necessary to import and use high-quality refined paint made by Japan to produce high-quality crafts that have not been properly passed down. Therefore, it was a long-cherished project that urgently needed to solve the development of refined lacquerware for lacquer crafts needed to properly protect and develop Korean lacquer culture.

However, despite numerous research institutes and researchers working on various methods for the development of excellently refined lacquer, the level of refined lacquer technology remains at about 40% of that of Japan, and the development of paint-related paint using the juice of cashew nuts with similar lacquer and molecular structure has been transformed into the lacquer and distributed to the market as if it had developed excellently refined lacquer. If tableware or spoons are produced using these products, consumers who use them can damage their health.

Therefore, seriously aware of this situation, I realized that Korea's correct refined lacquerware was necessary to correct the traditional lacquer culture. Together with the same researcher (Yoon Guk-jung), we developed a long-standing joint technology for 15 years (Study Period: 2004 - 2020) for the production of durable lacquer crafts with a constant curing speed (within 8 hours), hardness, color (transparent, black, color) viscosity, adhesion, and spreadability. For the first time in Korea, world-class refined lacquer (refined painting, transparent painting, black painting, and coloring) was developed, and various refined paints were developed for lacquer crafts (furniture, household goods, jewelry) with the strongest durability in the same class, including anti-cancer, antibacterial, preservative, and insect repellent.

■ Types of refined lacquer developed

The lacquer, a sap of lacquer, removes impurities such as hard lacquer particles and lumps and lacquer bark from the collection and increases harmless, antibacterial, preservative, insect repellent, hardness, gloss, transparency, flexibility, spread, attachability, and coloration. We have succeeded in developing world-class refined lacquer, such as refined painting, transparent painting (3 types), black painting (3 types), and colored lacquer (8 types) that satisfy the characteristics of lacquerware.

● Types of refined lacquer

- Raw lacquer: Removal of impurities through filtration and refining lacquer for basic use.

- Transparent lacquer: Homogeneous refined lacquer with high-gloss flexibility and curing speed, hardness, smoothness, adhesion, and transparency, removing impurities.

- Black lacquer: Homogeneous refined black paint with impurities removed, coloration, high gloss flexibility, curing speed, hardness, smoothness, and adhesion.

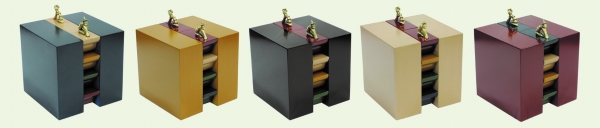

- Color lacquer: Colored lacquer produced by mixing pigments to express various colors, and refined lacquer used as a partial ornament for household items or ornaments.